G11-H Epoxy Fiberglass Laminated Sheet

Umyalelo weMveliso

Izixhobo ze-G11-H zonyango lwemichiza yombane owenziwe ngealkali-free fiberglass eyomeleziweyo, edityaniswe ne-TG ephezulu ye-epoxy resin.Inamandla omatshini aphezulu phantsi kobushushu obuqhelekileyo, isenamandla aqinileyo omatshini, iipropathi ezilungileyo zombane phantsi kokusingqongileyo okomileyo kunye nomanzi, zinokusetyenziswa kwindawo emanzi kunye ne-oyile ye-transformer.

Ukuthotyelwa kwemigangatho

Ngokuhambelana ne-GB/T 1303.4-2009 yombane thermosetting resin industrial hard laminates - Icandelo 4: epoxy resin hard laminates, IEC 60893-3-2-2011 insulating materials - zombane thermosetting resin industrial hard laminates - Icandelo 3-2 of the individual material08 specication EPGC.

Isicelo

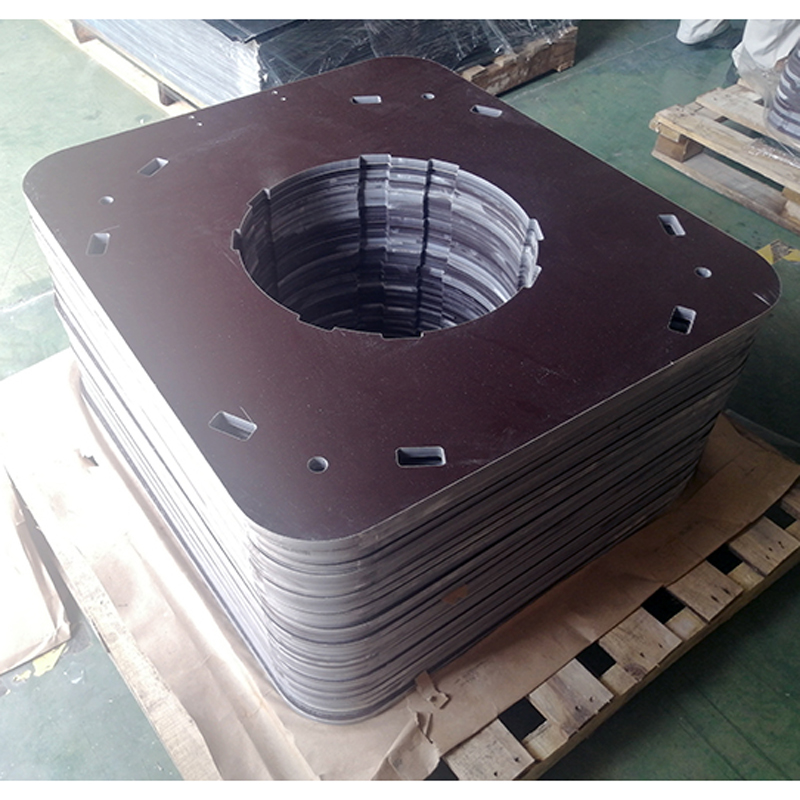

Ifanelekile kwiklasi ye-180 (H) yeenjini zokutsalela, iimotor ezinkulu njengee-slot wedges kunye nezixhobo zombane ezikwisiphelo esiphezulu njengeziphumo zokugquma ubushushu,

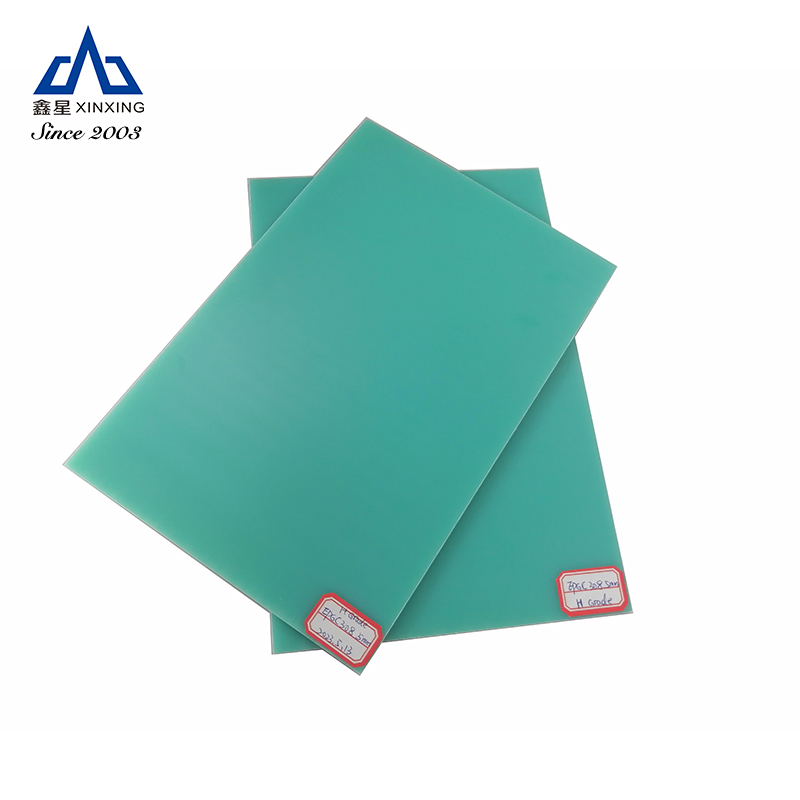

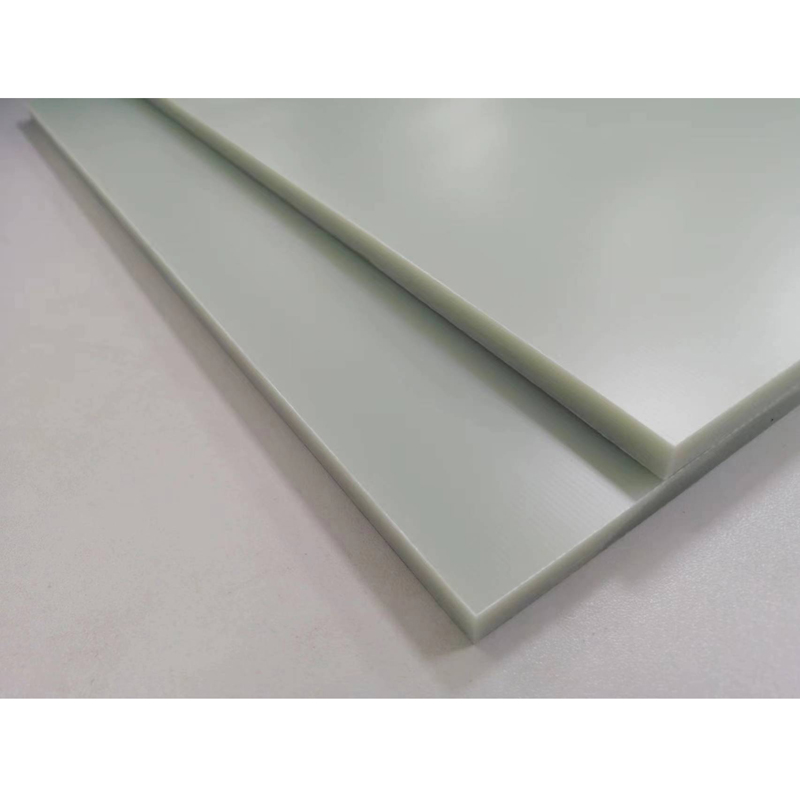

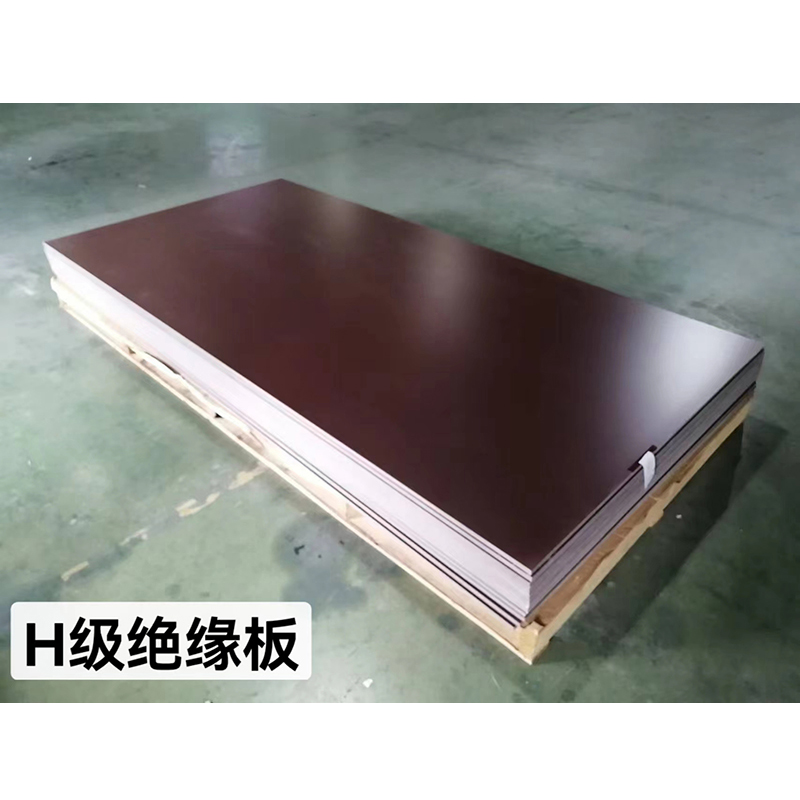

Imifanekiso yemveliso

Umhla ongundoqo wobuGcisa(Cofa apha ukukhuphela ingxelo yovavanyo lomntu wesithathu)

| Into | Ipropati | Iyunithi | Ixabiso eliMgangatho | Ixabiso eliqhelekileyo | Indlela yoVavanyo |

| 1 | Amandla e-Flexural perpendicular to laminations(MD,23℃±2℃) | MPa | ≥380 | 556 | GB/T 1303.2 |

| 2 | Amandla e-Flexural perpendicular to laminations(MD,180℃±2℃) | MPa | ≥190 | 298 | |

| 3 | Amandla e-Flexural perpendicular to laminations(MD,23℃±2℃) | MPa | _ | 24252 | |

| 4 | Amandla empembelelo ye-Charpy ehambelana ne-laminations (Notched, MD) | kJ/m2 | ≥37 | 111 | |

| 5 | Amandla okuqina (MD) | MPa | ≥300 | 557 | |

| 6 | Amandla acinezelayo alungeleleneyo kwizibane (23℃±2℃) | MPa | ≥380 | 640 | |

| 7 | Amandla acinezelayo axhomekeke kwizibane (180℃±2℃) | MPa | ≥190 | 378 | |

| 8 | Amandla ombane perpendicular to laminations(ku-90℃±2℃ kwi-25# i-oyile yesiguquli, ii-20s zovavanyo lwenyathelo nenyathelo,Φ25mm/Φ75mm cylindrical electrode) | kV/mm | ≥14.2 | 19.2 | |

| 9 | Ukonakaliswa kwamandla ombane adityaniswe ne-laminations (ku-90 ℃ ± 2 ℃ kwi-25# ye-oyile yesiguquli, i-20s yovavanyo lwenyathelo nenyathelo, Φ130mm/Φ130mm ipleyiti yombane wepleyiti) | kV | ≥45 | >100 | |

| 10 | Imvume ezalanayo(1MHz) | _ | ≤5.5 | 5.20 | |

| 11 | I-Dielectric dissipation factor (1MHz) | _ | ≤0.04 | 0.0102 | |

| 12 | Ukumelana ne-insulation emva kokuntywiliselwa emanzini (MD, taper pin electrode, 25.0mm gap) | Ω | ≥5.0 x1010 | 2.6x1014 | |

| 13 | Ukufunxwa kwamanzi | mg | ≤22 | 18.00 |

|

| 14 | Ukuxinana | g/cm3 | 1.7-2.0 | 1.98 | |

| 15 | Isalathisi sobushushu | ℃ | _ | 180℃ | |

| 16 | TG | ℃ | _ | 200℃±5℃ |

FAQ

I-Q1: Ngaba uyinkampani yokurhweba okanye umenzi?

Singumvelisi ohamba phambili we-composite yokugquma umbane, siye sazibandakanya kumvelisi we-thermoset rigid composite ukususela ngo-2003. Umthamo wethu yi-6000TONS / ngonyaka.

Q2: Iisampuli

Iisampulu zisimahla, kufuneka uhlawule kuphela intlawulo yokuthumela.

I-Q3: Uqinisekisa njani umgangatho wokuvelisa ngobuninzi?

Ngokubonakala, ubungakanani kunye nobukhulu: siya kwenza uhlolo olupheleleyo phambi kokupakisha.

Ngomgangatho wokusebenza: Sisebenzisa ifomyula emiselweyo, kwaye iya kuba kuhlolwa rhoqo isampuli, sinokunika ingxelo yokuhlola imveliso ngaphambi kokuthunyelwa.

I-Q4: Ixesha lokuhambisa

Kuxhomekeke kubungakanani bomyalelo.Ngokuthetha ngokubanzi, ixesha lokuhambisa liya kuba yi-15-20 iintsuku.

Q5: Iphakheji

Siza kusebenzisa iphepha lobuchwephesha lobugcisa ukupakisha kwi-plywood pallet.ukuba uneemfuno zephakheji ezikhethekileyo, siya kupakisha njengemfuno yakho.

Q6: Intlawulo

TT, 30% T/T kwangaphambili ,ibhalansi phambi kokuthunyelwa.Siyayamkela i-L/C.